SC 320

|

|

||||

|

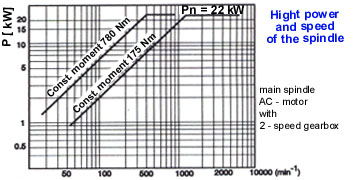

Rigid headstock construction for high - precision machining |

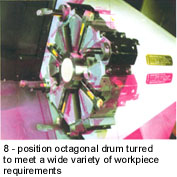

Turrets to meet wide tool requirements |

||||

|

|

||||

|

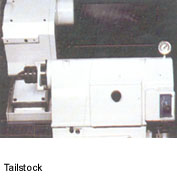

Fully automatic NC tailstock |

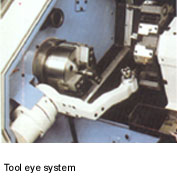

TOOL EYE to reduce tool setup time |

||||

|

|

||||

|

Unsurpassed operation-easy and reliability |

Designed for high - precision machining |

||||

|

|

||||

| More options for unmanned operation | Simplified and extremely fast NC programming | ||||

|

|

||||

|

|

||||

|

|

|

| SIEMENS SINUMERIK 840 C CNC SPECIFICATIONS | |

|

Program language |

DIN / ISO 66025 |

|

No. of controlled axis |

2-axis (X,Z), simultaneous 2-axis |

|

Control system |

positioning, linear and circular interpolation |

|

Command system |

absolute (manual program mode: absolute/incremental) |

|

Last input increment |

X,Z-axis 0,001 mm (X-axis dia.) |

|

Max. programmable dimension |

X,Z-axis ±99999,999 mm |

|

Cutting feed rate |

X,Z-axis 0,001-90000 mm/rev. |

|

Memory capacity |

32000 programs |

|

Automatic programming |

cutting conditions, tool path, etc. |

|

Automatic program checking |

program contour check (while programming), tool path check, simulation check, tracing, arbitrary display scale |

| Background programming | simultaneous machining and programming |

| STANDARD ACCESSORIES | |

|

Hydraulic through hole chuck |

ø 250 mm (with 1 set of soft jaws) |

|

Measuring tool system |

convenient tool set-up, tool wear measurement, and broken tool detection |

|

Coolant system (with 320 W pump) |

190 liter tank capacity for universal |

|

Lighting equipment |

work light and electrical cabinet maintenance light |

|

Safe and clean working enviroment |

front cover totally encloses machining area |

|

Adjusting tool |

parts list |

|

One set of manuals |

programming / operation / maintenance |

|

Tooling package |

differs by turret type |

|

Door interlock |

door open/close is confirmed by sensor and interlockied for automatic operation |

|

Hydraulic pressure interlock |

in case of low hydraulic pressure spindle rotation and axis movement will stop |

|

OPTIONAL ACCESSORIES |

|

|

Large spindle bore ø 104 mm Automatic door close/open |

|

|

Machining completion indicator light |

|

|

Chuck air blast |

|

|

High-power coolant system |

|

|

Chip conveyor |

|

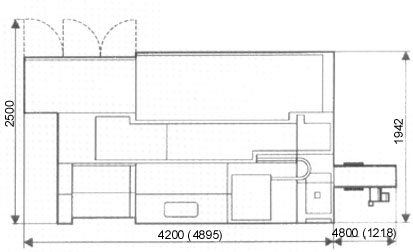

| Floor Space |

|