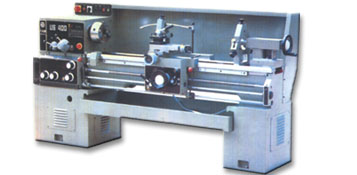

US - 400

|

|

|

|

Purpose |

|

|

| Main spindle | |

|

|

|

Slide ways |

|

|

|

| Accuracy class | |

|

|

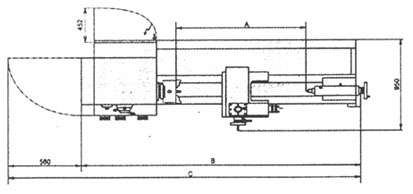

| Choise of lengths | |

|

|

| BUILT - IN EQUIPMENT |

VARIANTS |

|

|

Coolant device |

A |

Conventional, length (750; 1.000; 1.500) with a set of standard accessories |

|

Safety door |

B |

Universal lathe (560 x 200) |

|

Working light |

C |

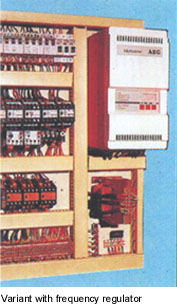

Continuous change of main spindle rotations (frequency regulator) |

| Floor Space |

D |

Productive lathe with standard accessories |

|

E |

Conventional, with device for cone turning |

|

F |

Special variant, with column milling machine, i.e. drilling machine | |

|

G |

Universal lathe with pneumatic clamping device for the workpiece and pneumatic quill travel | |

|

H |

Universal lathe for cylindrical external and inner grinding | |

| I | Universal lathe for fast clamping device for rod materials | |