US - 400 STEP

|

|

| Purpose | Main spindle |

|

|

|

Slide ways |

Screw spindle |

|

|

|

Program language

DIN/ISO 66025

Number of controlled axis

2-axis (X,Z), simultaniusly 2-axis

Control system

positioning, linear and circular interpolation

Command system

apsolute (manuel program mode: absolute / incremental)

Last input increment

X,Z-axis 0,005mm (X-axis by diametar)

Feed rate

X,Z 10.000 mm/min

Memory capacity

256 KB @ 50 programs

Automatic programing

DIN simulation

15 tools with 30 tool offsets

Program execution via external DNC

Data transmission via RS232C

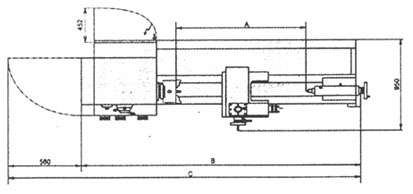

| DIMENSION |

Floor Space |

|

|

Lenght |

2.010 mm |

|

|

Width |

1.050 mm |

|

|

Hight |

1.480 mm |

|

|

Weight |

1.600 kg | |