V - 90L & V - 70 L

|

|

||||||

|

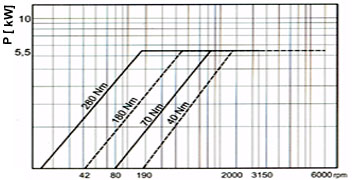

High power and speed of the spindle motor |

Rigid spindle-head designed for high - accuracy |

||||||

|

|

||||||

|

Large working area |

High-precision |

||||||

|

|

||||||

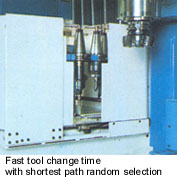

| Tool magazine capacities to meet any requirement |

Pallet changer system |

||||||

|

|

||||||

| Many features for automatic operation | Simplified and extremely fast NC programming | ||||||

|

|||||||

| More options for unmanned operation | Simplified and extremely fast NC programming | ||||||

|

|

||||||

|

|

||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SIEMENS SINUMERIK 802 D FUNCTION OVERVIEW | |

|

CNC Programming |

programming language DIN 66025

|

|

Operation |

|

|

Tool offsets |

|

|

Axis / Spindle functions |

|

|

Data transmission |

|

| STANDARD ACCESSORIES | |

|

Chiller unit |

|

|

Air blast |

|

|

Splash guard |

|

|

Automatic tool length measuring system |

|

|

Tool life monitoring and spare tool changeover function |

|

|

Tool breakage detection / recovery system |

|

|

Work light |

|

|

Adaptive feedrate control function |

|

|

Adjusting tools |

|

|

Manuals |

|

|

OPTIONAL ACCESSORIES |

|

| Twin pallet changer | |

|

Automatic centering function |

|

|

Provision for oil hole drill |

|

|

Linear scale feedback system |

|

| Provision for tap coolant |

|

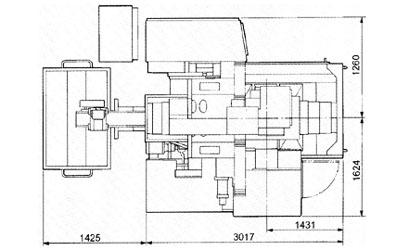

| Floor Space |

|